1. Overview: Rotary sanyaya inji ne babban inji na zafi da ruwan sama da yawa na kayan bayan bushewa. The inji ne daya daga cikin manyan kayan aiki a cikin taki masana'antu, wanda aka yi amfani da shi don sanyaya da ƙirar taki ƙirar, a lokacin da ƙirar zafin jiki rage lokaci guda ruwa abun ciki rage, da ƙirar ƙarfin ƙirar ma daidai. The inji ta hanyar haɗi da iska mai zafin jiki a matsayin fitar da iska a kan injin zai ci gaba da cire iska mai zafin jiki daga injin sanyaya a ƙarshen tushen daga sama da rufi, yayin da jikin ya ci gaba da juyawa, da ciki ɗaga allon zai ci gaba da sanya ƙwayoyin sama da jefa, sa kayan da sanyi iska cikakken tuntuɓar, samar da zafi musayar, don haka cimma manufar daidai sanyaya.

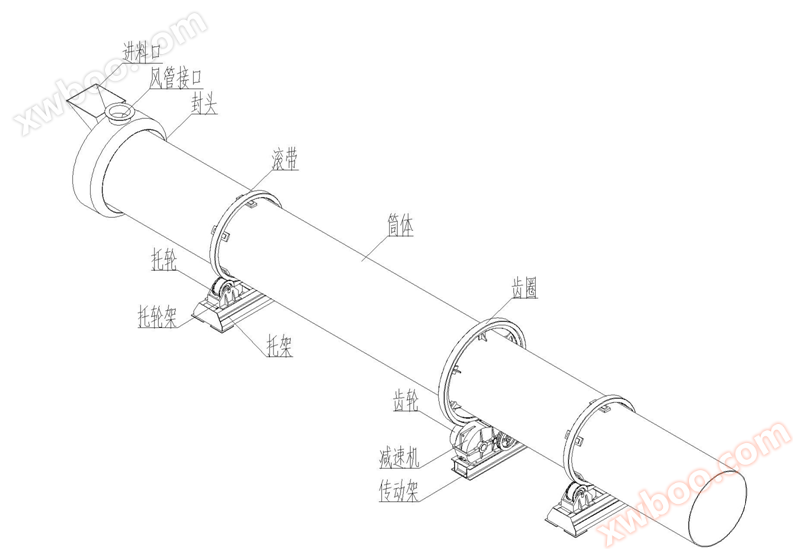

2. Tsarin: An iya raba dukan injin zuwa manyan sassa huɗu:

a. rack sashi: rack sashi ya hada da gaban rack da kuma bayan rack, wanda aka kafa a kan daidai tushe, don tallafawa silinda jiki don positioning juyawa. Gaba da baya racks sun kunshi da racks, racks, wheels. Lokacin shigarwa za a iya daidaita na'urar tsawo da kusurwa ta hanyar daidaita nisan ƙafafun ƙafafun biyu a gaba da baya.

b. Transmission sashi: Transmission sashi samar da ikon da ake bukata ga dukan na'urar rufi aiki daidai. Abubuwan da suka haɗa da motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar motar

c. Silinda Jiki: Silinda Jiki ne aiki bangare na dukan sanyaya. A waje akwai madaidaiciya band don tallafi da kuma hakora zoben da aka yi amfani da shi don motsa jiki, ciki walda ɗaga allon a cikin layered rarraba, a lokacin da sanyaya inji aiki ci gaba da ɗaga, hashewa kayan samar da zafi musayar don cimma sanyaya manufa.

d. rufe kai, rufe ƙarshe, iska bututu: Wannan sashi ya kafa sanyi iska zagaye, ƙura removal tsarin da ake bukata a cikin aikin sanyaya. Kyakkyawan rufi tsakanin kai da wuraren haɗin jiki, don haka iska mai sanyi ta ci gaba da rage zafin jiki na farfajiyar ƙwayoyi don cimma manufar sanyaya ƙwayoyi daidai. Idan mai aiki yana buƙatar shiga ciki na silinda don aiki, don Allah shiga daga baya a lokacin dakatarwa.

3. Abubuwa

Our kamfanin haɓaka juyawa sanyaya yana da wadannan fasali:

a. Ƙananan zuba jari, saurin aiki, da kuma ingancin farashi.

b. ƙananan wutar lantarki, low makamashi amfani, aiki kwanciyar hankali, sauki maintenance.

c. Rarraba da kuma kusurwar zane mai kyau, ingantaccen aiki, saboda haka musayar zafi tana da inganci, sanyaya daidai, da ƙananan lokacin tsaftacewa.

1. Main fasaha sigogi

Wannan jerin na'urar sanyaya na rotor yana da nau'ikan nau'ikan, za a iya sayen su bisa ga bukatun masu amfani da samar da kayayyaki, kuma za a iya yin su, tare da babban zaɓi, manyan sigogin fasaha suna ganin teburin da ke ƙasa:

samfurin |

Diamita (mm)

|

tsawon (mm)

|

Bayan shigarwa girman(mm)

|

juyawa Speed (m / min)

|

Injin lantarki samfurin

|

ikon (kw)

|

TS0880 | 800 | 8000 | 9000×1700×2400 | 6 | Y132S-4 | 5.5 |

HG10100 | 1000 | 10000 | 11000×1600×2700 | 5 | Y132M-4 | 7.5 |

HG12120 | 1200 | 12000 | 13000×2900×3000 | 4.5 | Y132M-4 | 7.5 |

HG15150 | 1500 | 15000 | 16500×3400×3500 | 4.5 | Y160L-1 | 15 |

Suka18180 | 1800 | 18000 | 19600×3300×4000 | 4.5 | Y225M-6 | 30 |

HG20200 | 2000 | 20000 | 21600×3650×4400 | 4.3 | Y250M-6 | 37 |

HG22220 | 2200 | 22000 | 23800×3800×4800 | 4 | Y250M-6 | 37 |

HG24240 Mai | 2400 | 24000 | 26000×4000×5200 | 4 | Y280S-6 | 45 |

II. Shigarwa da debugging da kuma kulawa

1. Shigarwa:

Bayan na'urar zuwa masana'antar, daidai da tsarin da aka sanya a kan tushen kankare mai dacewa, kullum kusurwar karkata ita ce digiri 2.3 (za a iya daidaitawa bisa ga bukatun mai amfani). Ana sanya na'ura rack da drive rack a kan kankare pilaster, bayan daidaita matsayi tare da pre-buried walda a daya. Tsakanin kowane tushe da tushe, kamar yadda ake buƙata a cikin wani wedge pad panel, kauri ya kamata ba ya fi 35mm.

a. Kayan aiki ya kamata ya zama tushe kafin shigarwa, bayan sarrafa kankare za a iya shigar da kayan aiki.

b. Daidaita tsawo na kowane tushe tare da wedge pad kamar yadda ake buƙata don jigon ya kiyaye kusurwar da ake buƙata.

c. Bayan daidaita da wheelchair rack zuwa daidai wuri sanya silinda a kan wheelchair, da kuma daidaita daban-daban sassa spacing.

d. Shigar da motsi sashi na sanyaya, daidaita da kyau kayan aiki da haƙori circles.

2. gyara:

a. Lokacin gwajin motar kula da jikin juyawa shugabanci, karamin kayan aiki da manyan hakora zoben ya kamata juyawa baya, idan jikin juyawa shugabanci ba daidai ba to, daidaita mataki.

b. Zafin jiki na kowane bearing ya kamata ya tashi a hankali, da kuma bearing zafin jiki ba ya kamata ya fi 50 ° C lokacin amfani da dogon lokaci.

c. hayaniya na kayan aiki ya kamata daidai, ba ya kamata a watsi da sama da ƙasa.

d. Bayan gwajin mota karshen lura da Rolling band, wheels, kayan aiki, hakora circles, da dai sauransu ba za a iya samun mummunan lalacewa.

3. Kulawa da kulawa:

a. Dole ne a kara lubricating man kafin yin amfani da reducer, lubricating man gabaɗaya amfani da HJ40-50 inji man fetur, kuma za a iya amfani da HL20-30 kayan aiki man fetur. Ya kamata tsawon man fetur ya kasance a cikin kewayon alamar alamar man fetur a kan wurin zama. Bayan sa'o'i 100 na aiki na farko, ya kamata a maye gurbin sabon man fetur, sannan a maye gurbin kowane watanni huɗu, a tsabtace lokacin maye gurbin man fetur.

b. Bearing buga sau daya lubricating man, lubricating man samfurin ne No. 3 calcium tushen fat lubricating man, loading adadin ne 1/3 ~ 1/2, da kuma a kai a kai maye gurbin sabon lubricating man, a lokacin maye gurbin don wanke.

c. Kayan aiki, hakora zoben, Rolling band, Wheels da sauransu a surface juna don bushewa da butter.

4. m sassa

a. triangular band b. bearing c. mai haɗin gwiwa pin

3. Amfani da aiki

1. Farawa:

a. Apply bushe man sau a kan kayan aiki da kuma Rolling band, allura adadin man sau ko kayan aiki man sau a kan bearing wurin zama, reducer.

c. Bude dust remover iska na'urar bayan fara jigilar kayan aiki, sanyaya cylinder kauce wa fara da kayan aiki.

2. filin ajiye motoci:

A biyu dakatar da kayan aikin daban-daban na aikin kafin na'urar sanyaya, har sai kayan da ke cikin na'urar sanyaya su fitar tsabta, a biyu dakatar da kayan aikin daban-daban na aikin baya.

3. Lura:

a. A lokacin da na'urar sanyaya ke aiki, an hana ma'aikatan wucewa daga ƙarƙashin jikin.

b. An hana binciken ciki da gyaran lokacin da injin sanyaya ke aiki.

c. Ba a sanya hannu mai rufi ba, an hana taɓa motar lantarki da wayoyi.

d. Babu cikakkiyar ƙasa, an hana kunna sanyaya, idan an gano cewa akwai halin yanzu a kan na'urar ya kamata a dakatar da shi nan da nan har sai an gyara ƙasa.

4. Common matsaloli da kuma magance hanyoyin

Rashin aiki | 故障原因 | Hanyar fitarwa |

Rolling Band Sliding | Babu clamping gefen concave junction na Rolling band | Clamping gefen Rolling band da concave haɗi |

Babu clamping a cikin radius shugabanci tare da Rolling band da concave haɗi | Ta amfani da pads board ko wedges don sanya ruwa band da kuma concave haɗi clamped, amma dole ne a lura da excess clamping sauki hadari, yayin da m jawo sauki haifar da jiki buga da rawar jiki |

Kuskuren jiki | Wheel lalacewa | Gyara ko maye gurbin wheels bisa ga darajar lalacewa |

Wheel lalacewa | Motsa ko maye gurbin sabon motar dangane da matakin lalacewa |

Kuskuren Giya | Ƙananan gear lalacewa | Shigar da kayan aiki a baya, idan duka bangarorin sun lalace, yana buƙatar maye gurbin sabon kayan aiki |

Babban gear da kuma silinda tsakiyar haɗin da aka lalata | Kulawa da haɗin kai idan ya zama dole |

Cylinder vibration | An lalata haɗin haɗin na'urar tare da tushe | Calibration haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin haɗin |

Rolling band gefen wear | Bi matakin lalacewa juyawa gefen Rolling band ko maye gurbin sabon Rolling band |